Molybdenum Disulfide

-

Hot

Molybdenum Disulfide

As the main component of molybdenite, molybdenum disulfide is black solid powder with metallic luster. Molybdenum disulfide has stable properties. Molybdenum disulfide is insoluble in water, dilute acid and concentrated sulfuric acid. Generally, molybdenum disulfide is insoluble in other acids, alkalis and organic solvents, but molybdenum disulfide is soluble in aqua regia and boiled concentrated sulfuric acid.

Send Email Details

Molybdenum Disulfide is a lubricant grade of molybdenum disulfide (MoS2) available in three grades-Technical, Technical Fechnical Fine, and Super Fine.Typical MoS2 content (calculated average) is 98.5%.

Molybdenum Disulfide is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulfide can be lubricated for a long time in the air below 350℃.

With more than ten years of R&D experience, it can provide an annual output of 1,000 tons of Molybdenum Disulfide as a patented technology product. -

Hot

MoS2 Spray

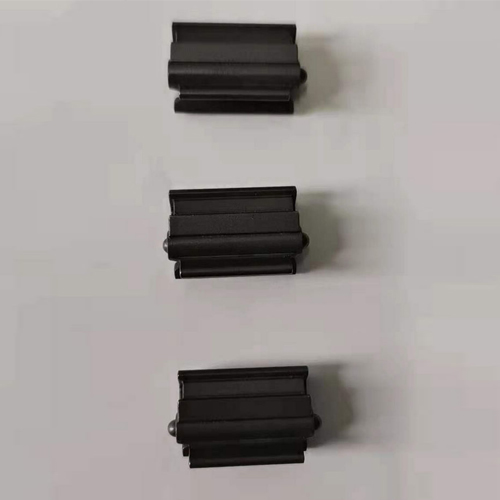

MoS2 Spray is a dry lubricant designed to provide long-lasting lubrication especially for lightly loaded or slowly moving to heavily loaded sliding surfaces. MoS2 Spray can form a solid molybdenum disulfide dry film on the surface of the parts, which can reduce friction and wear, and at the same time protect the parts from corrosion/seizing, contamination or wear.

Send Email Details

MoS2 Spray is widely used in sliding parts, including plain bearings, gears, sliding systems, cams and valves, with an operating temperature range of up to 450°C. -

MoS2 Technical Fine Grade

MoS2 Technical Fine Grade has strong corrosion resistance, compression resistance, high vacuum resistance, radiation resistance and adhesion to metals. .

Send Email Details

MoS2 Technical Fine Grade is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and MoS2 Technical Fine Grade can be lubricated for a long time in the air below 350 ℃.

With more than ten years of research and development experience, it can provide an annual output of 550 tons of MoS2 Technical Fine Grade as a patented technology product.

MoS2 Technical Fine Grade is a lubricant grade of molybdenum disulfide (MoS2). Typical MoS2 content (calculated average) is 98.5%. -

MoS2 Technical Grade

MoS2 Technical Grade is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and MoS2 Technical Grade can be lubricated for a long time in the air below 350 ℃.

Send Email Details

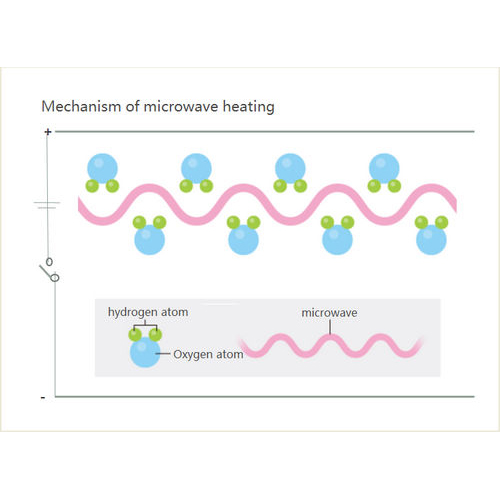

With more than ten years of research and development experience, it can provide an annual output of 550 tons of MoS2 Technical Grade as a patented technology product. In the production process of MoS2 Technical Grade , microwave heating technology is introduced, and the water molecules in the slurry absorb microwave energy to achieve uniform and rapid heating, and to achieve production automation and stable quality.

MoS2 Technical Grade is a lubricant grade of molybdenum disulfide (MoS2). Typical MoS2 content (calculated average) is 98.5%. -

Nano Molybdenum Disulfide

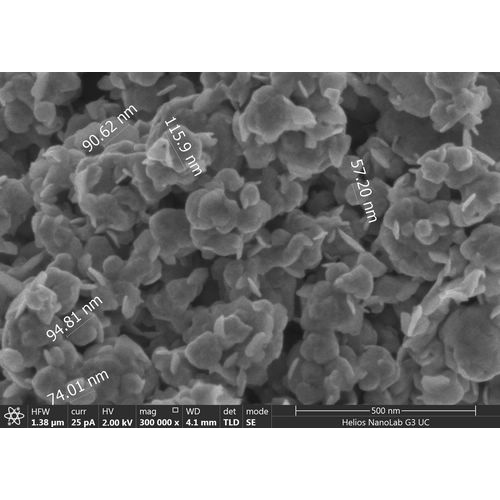

Compared with conventional molybdenum disulfide, the number of surface atoms in Nano molybdenum disulfide is significantly increased, and more sulfur vacancies are formed, which makes the catalytic activity and selectivity of Nano molybdenum disulfide higher. Nano molybdenum disulfide can be used as a highly active hydrogenation catalyst for heavy oil conversion and fuel oil refining. Nano molybdenum disulfide is used as a catalyst in the process of carbon monoxide methanation with high selectivity and reactivity. Nano molybdenum disulfide is also a catalyst for coal liquefaction.

Send Email Details

When used in the petrochemical industry, Nano molybdenum disulfide is a good catalytic hydrodesulfurization catalyst. Nano molybdenum disulfide that meets different functional requirements can be prepared by different methods, such as molybdenum disulfide self-lubricating thin layer, molybdenum disulfide intercalation battery, molybdenum disulfide high-efficiency hydrodesulfurization catalyst, etc. As the particle size of MoS2 becomes smaller, the adhesion and coverage of molybdenum disulfide on the surface of the friction material are significantly improved, and the anti-wear and anti-friction properties of molybdenum disulfide are also doubled. The energy band difference of the ultra-fine Nano molybdenum disulfide thin layer is close to 1.78eV, which matches the energy of light, and has application prospects in photovoltaic cell materials. -

Hot

Molybdenum Disulfide Technical Fine Grade

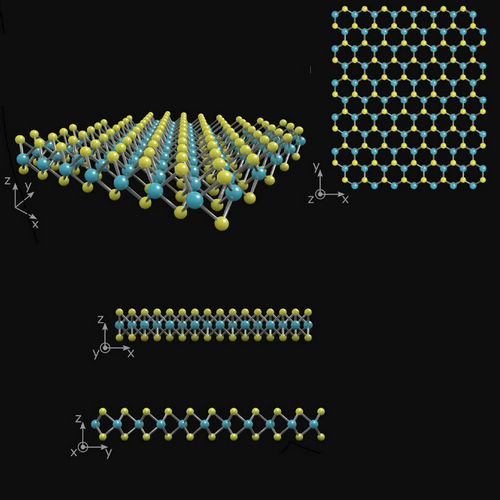

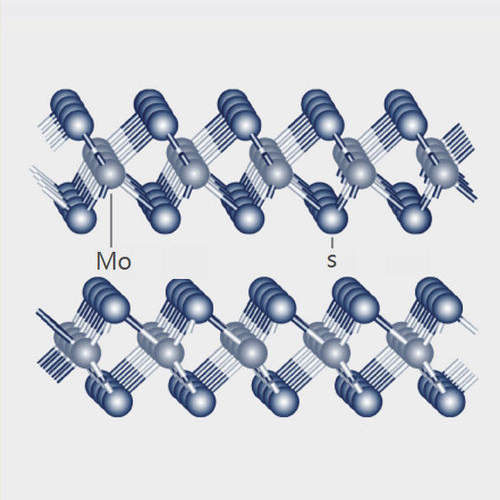

Molybdenum Disulfide Technical Fine Grade is a diamagnetic compound with semiconducting properties. The Mo-S facets in molybdenum disulfide are quite large, the specific surface area is large, the inner layer is a strong covalent bond, and the interlayer is a weak van der Waals force, The layers are easily peeled off, with good anisotropy and low friction coefficient.

Send Email Details

Molybdenum Disulfide Technical Fine Grade is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulfide Technical Fine Grade can be lubricated for a long time in the air below 350 ℃.

With more than ten years of research and development experience, it can provide an annual output of 550 tons of Molybdenum Disulfide Technical Fine Grade as a patented technology product.

Molybdenum Disulfide Technical Fine Grade is a lubricant grade of molybdenum disulfide (MoS2). Typical MoS2 content (calculated average) is 98.5%. -

Molybdenum Disulfide Lubricating Paste

Molybdenum Disulfide Lubricating Paste is a quick-drying lubricant. Molybdenum Disulfide Lubricating Paste is also known as Molybdenum Disulfide Lubrication , Molybdenum Disulfide Lubricant ,and Molybdenum Disulfide Quick-drying Lubricant. Molybdenum Disulfide Lubricating Paste can provide long-lasting lubrication for sliding surfaces with light load or slowly moving to heavy load. Molybdenum Disulfide Lubricating Paste can be used for sliding parts with an operating temperature range of up to 350°C, including rollers, flat bearings, gears, sliding systems, cams and valves.

Tips on how to use Molybdenum Disulfide Lubricating Paste:Shake the tank before use to mix the liquid in the tank evenly. For best results, please wipe clean the parts to be sprayed. Use a brush to evenly coat the surface of the part, and the coating thickness is recommended to be no more than 0.5mm.Molybdenum Disulfide Lubricating Paste Molybdenum Disulfide Lubrication Molybdenum Disulfide LubricantSend Email Details -

Molybdenum Disulfide Superfine Grade

Compared with molybdenum disulfide technical grade and Molybdenum disulfide technical fine grade, Molybdenum Disulfide Superfine Grade has incomparable advantages in industrial applications. Molybdenum disulfide itself has good lubricating properties. However, Molybdenum Disulfide Superfine Grade has high temperature, low temperature, high load, high speed, chemical corrosion and modern ultra-high temperature. Under vacuum conditions, Molybdenum Disulfide Superfine Grade has more excellent lubricity for equipment.

Send Email Details

Molybdenum Disulfide Superfine Grade is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulfide Superfine Grade can be lubricated for a long time in the air below 350 ℃.

With more than ten years of research and development/ R&D experience, we can provide an annual output of 1,000 tons of Molybdenum Disulfide Superfine Grade as a patented technology product. -

Molybdenum Disulfide For Wiper

Molybdenum Disulfide For Wiper is added to the wiper body in the form of powder, which can be used for high-power generators and starter generators. The actual service life is 600 hours. Molybdenum Disulfide For Wiper is also successfully used in the main generator of helicopters with a service life of more than 500 hours.

Send Email Details

With more than ten years of R&D experience, we can provide an annual output of 1,000 tons of Molybdenum Disulfide For Wiper as a patented technology product.

Molybdenum Disulfide For Wiper is a lubricant grade of molybdenum disulfide (MoS2) available in two grades-Technical Fechnical Fine,and Super Fine.Typical MoS2 content (calculated average) is 98.5%.