Thriving New Materials to Showcase at PM China 2026

Breaking Technological Monopoly with "Hydrocyclone Separation Method" for Non-Acid Leached Molybdenum Disulfide

Introduction:

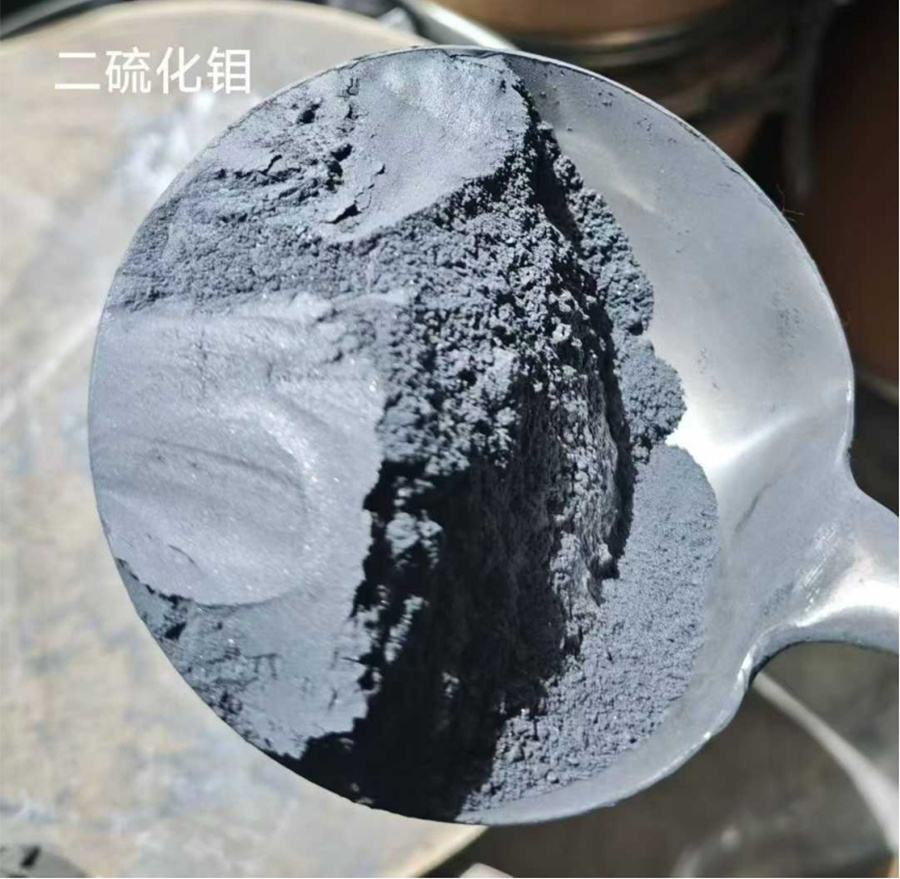

As the 2026 Shanghai Powder Metallurgy & Hard Alloy Exhibition approaches, Thriving New Materials Co., Ltd., a company with nearly 20 years of expertise in molybdenum disulfide, announces that it will make a grand appearance featuring its product — high-purity molybdenum disulfide prepared using the purely physical "Hydrocyclone Separation Method" without acid leaching. This move marks Thriving New Materials' successful breakthrough in overcoming foreign technological monopolies, providing a green, environmentally friendly, and strong-acid-residue-free material solution for industries such as powder metallurgy, lubrication, and composite materials, bidding farewell to the risks of strong acid pollution and residue associated with traditional acid leaching processes.

I. Breaking the Monopoly: From "Acid Leaching" to "Hydrocyclone," Ushering in a New Era of Pure Physical Purification

For a long time, the production technology for high-purity molybdenum disulfide has been highly guarded. The traditional mainstream process heavily relies on highly corrosive chemicals such as hydrofluoric acid and hydrochloric acid for acid leaching purification. This method not only poses serious challenges to production equipment and personnel safety but also leaves behind acid residues that are difficult to eliminate, acting like a "hidden bomb" that continuously threatens the long-term stability and reliability of downstream products. This presents significant usage and safety risks, especially in applications involving precision components such as sealing materials, valve guides, greases, and brake pads.

After nearly two decades of R&D by its core team, Thriving New Materials has successfully introduced and innovated the "Hydrocyclone Separation" physical purification process. This technology abandons the use of strong acids and alkalis such as hydrofluoric acid, hydrochloric acid, and sodium hydroxide. Through multi-stage precision physical purification, high-purity molybdenum disulfide is extracted directly from molybdenum concentrate that has not been chemically contaminated. The company has fully obtained ISO 9001, ISO 45001, and ISO 14001 management system certifications, ensuring product quality and production safety from the source.

II. Product Revolution: Defining a New Standard for "Green, Environmentally Friendly, Strong-Acid-Residue-Free" Molybdenum Disulfide

The "Hydrocyclone Separation" Non-Acid Leached Molybdenum Disulfide showcased by Thriving New Materials this time represents asubversion of traditional products.

Purity: The product fundamentally avoids hydrofluoric acid residue and hydrochloric acid residue. Only trace amounts of weak molybdic acid are generated due to powder pulverization, demonstrating excellent performance in copper strip corrosion tests and meeting stringent application requirements.

Stable Performance: The physical method preserves the natural layered crystal structure of molybdenum disulfide, resulting in more consistent and stable performance in lubricity, friction reduction, wear resistance, and composite material enhancement.

Green: The entire process produces no strong acid fumes and discharges no toxic wastewater, achieving full lifecycle green practices from production to application. It stands as a benchmark material in response to carbon neutrality goals.

III. Market Validation: Garnering Favor from Industry Giants at Home and Abroad, Comprehensive Cooperation Underway

Since achieving mass production in 2025, this innovative product has rapidly gained validation at the market forefront. Its core advantages of no acid residue and high stability have attracted high attention from industry enterprises including petrochemical companies, Synergy Grease, Anqing TPR, GKN, Mobil, Shell, and Dow Corning. Currently, Thriving New Materials has entered into in-depth cooperation discussions and product validation stages with numerous giants, indicating that its product performance and philosophy have gained preliminary recognition in the high-end market.

IV. Looking Ahead: Showcasing at PM China, Jointly Expanding the New Landscape of Green Materials

In response to the manufacturing industry's escalating demands for carbon neutrality, material safety, environmental protection, and reliability, Thriving New Materials will leverage the platform of the 2026 Shanghai Powder Metallurgy & Hard Alloy Exhibition to fully accelerate market promotion and cooperation network development.

We sincerely invite partners, industry experts, and media friends to visit the Thriving New Materials booth to witness firsthand the quality of "Hydrocyclone Separation" Non-Acid Leached Molybdenum Disulfide. Let's explore together the green future and application possibilities of molybdenum disulfide materials, and jointly promote the development of the powder metallurgy and related industries towards a more sustainable direction.

About Thriving New Materials Co., Ltd.:

Thriving New Materials Co., Ltd. is a technology-driven enterprise long focused on the R&D, production, and sales of high-performance molybdenum disulfide. With "Innovation-Driven, Green Manufacturing" at its core, the company is committed to providing global customers with safe, reliable, and environmentally friendly molybdenum disulfide products and solutions through its self-developed advanced physical purification technology.

#ThrivingNewMaterials #MolybdenumDisulfide #HydrocycloneSeparationMethod #NonAcidLeached #AcidResidueFree #PowderMetallurgy #PMShanghai #TechnologyBreakthrough #GreenManufacturing #SolidLubricant